· Product Introduction

· Model

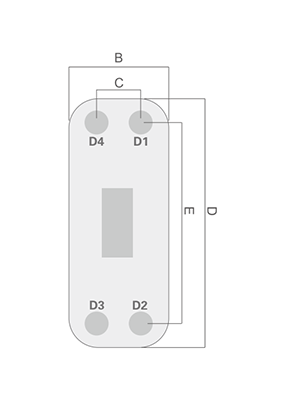

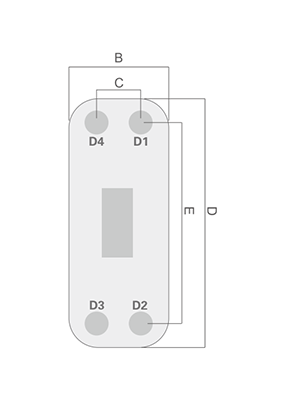

ZL28 |

B(mm) 120 | C(mm) 72 | D(mm) 290 | E(mm) 243 | Thickness ( mm ) 10+2.36N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 1.5+0.133N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Fully welded brazed heat exchangers are a type of heat exchanger that utilizes a brazing process to join the components together without the use of gaskets or bolts. This construction method results in a compact, durable, and efficient heat exchanger suitable for a wide range of applications.

Here are some key features and benefits of fully welded brazed heat exchangers:

Leak-Free Design: Since there are no gaskets or bolts, fully welded brazed heat exchangers offer a leak-free design, which is critical in applications where fluid leakage could be problematic.

High Thermal Efficiency: The brazed joints provide excellent thermal conductivity, which can lead to higher overall heat transfer efficiency compared to heat exchangers with gasketed connections.

Compact Size: The lack of gaskets and bolts allows for a more compact design, making these heat exchangers ideal for applications where space is at a premium.

Corrosion Resistance: The brazed joints are typically made from materials that are resistant to corrosion, such as copper or nickel alloys, which can extend the life of the heat exchanger in harsh environments.

Low Maintenance: With no gaskets to replace and no bolts to tighten, fully welded brazed heat exchangers require minimal maintenance over their lifetime.

High Pressure and Temperature Ratings: These heat exchangers can be designed to withstand high pressures and temperatures, making them suitable for demanding industrial applications.

Customization: Depending on the manufacturer, fully welded brazed heat exchangers can be customized to meet specific application requirements, including different plate patterns, materials, and sizes.

Reliability: The hermetic seal provided by the brazing process ensures that the heat exchanger is reliable and consistent in operation.

Application Versatility: They can be used in various applications, including HVAC systems, industrial processes, refrigeration, and heat recovery systems.

Long Service Life: The robust construction and materials used in fully welded brazed heat exchangers contribute to a long service life, reducing the need for frequent replacements.