· Product Introduction

Brazed heat exchangers are one of the most effective ways of heat transfer. The design purpose of brazed plate heat exchangers is to provide unparalleled performance and the lowest lifecycle cost. If brazing technology can be enabled for your next heating or cooling project, it will bring you many benefits, including saving space, energy, and maintenance costs.

Subcoolers are used to cool the liquid refrigerant slightly below its saturation temperature, ensuring that no flash gas is formed before it reaches the expansion valve. This process enhances the system's efficiency and capacity. Brazed plate heat exchangers (BPHEs) are often utilized for subcooling due to their high heat transfer performance, reliability, and cost efficiency.

· Model

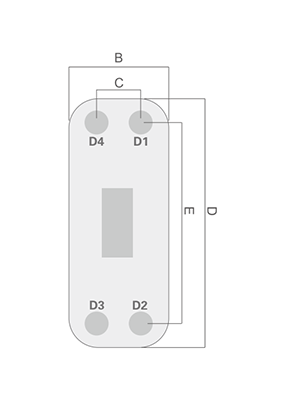

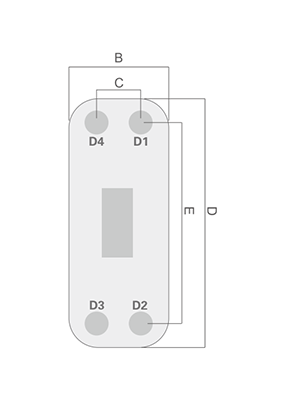

ZL28B |

B(mm) 120 | C(mm) 72 | D(mm) 290 | E(mm) 243 | Thickness ( mm ) 10+2.36N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 1.5+0.133N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.