Product Introduction

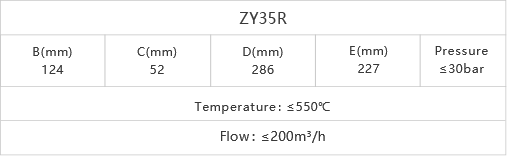

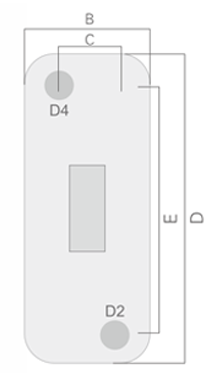

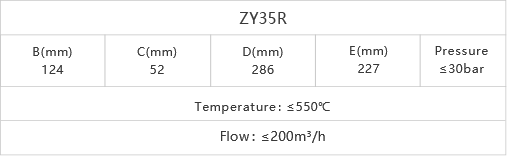

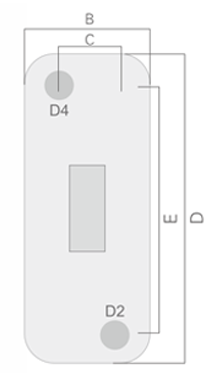

Model

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Fusion-bonded plate heat exchangers represent an advanced technology in heat transfer equipment, providing several key benefits and features that make them suitable for a range of demanding applications. Here are some of the main characteristics of fusion-bonded plate heat exchangers:

All Stainless Steel Construction: These heat exchangers are made entirely of stainless steel, which provides superior corrosion resistance and makes them ideal for hygienic applications where contamination from materials like copper or nickel is unacceptable.

High-Pressure and Temperature Capabilities: Fusion-bonded heat exchangers can handle extremely high pressures and temperatures, making them suitable for challenging applications such as those involving aggressive media like ammonia or in environments with extreme thermal and pressure conditions.

Compact Design: Despite their high capacity, these heat exchangers are extremely compact, which reduces installation costs and saves space.

High Thermal Efficiency: The uniform material throughout the heat exchanger contributes to high thermal efficiency, and the optimized plate design with asymmetric channel configuration provides maximum efficiency in demanding applications.

Virtually Maintenance-Free: Fusion-bonded plate heat exchangers require minimal maintenance, offering a low total cost of ownership.