Product Introduction

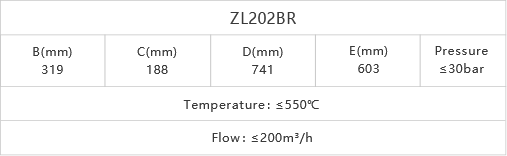

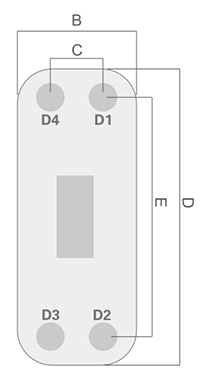

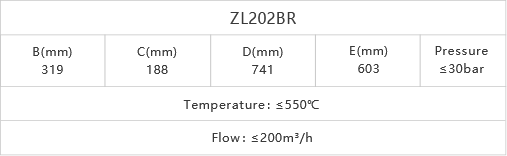

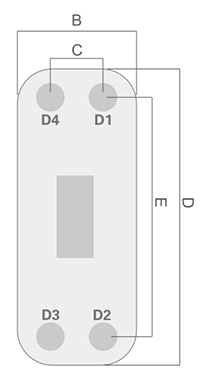

Model

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

All stainless steel fusion welded plate heat exchangers offer several distinct advantages over brazed plate heat exchangers (BPHEs), particularly in environments with extreme temperature changes, high pressures, and corrosive media.

Plate Heat Exchangers (PHEs) play a central role in Coolant Distribution Units (CDUs), primarily used in the liquid cooling systems of data centers. Here are some key application details of plate heat exchangers in CDUs:

System-Level Cooling Component: The plate heat exchanger, as part of the CDU, is responsible for dissipating heat generated by processors in data centers.

Liquid-to-Liquid Heat Exchange Principle: CDUs utilize this principle to transfer server waste heat to the facility cooling loop through the plate heat exchanger, while keeping the cooling liquid and waste heat liquid separate to prevent contamination.

Hot-Swappable Functionality: The CDU, which houses the plate heat exchanger, is designed to allow maintenance without system downtime, enhancing system reliability and maintainability.

Temperature Control: A built-in proportional valve is used for precise control of the CDU outlet temperature, ensuring stable temperatures for the data center equipment.

Redundant Pump System: Dual pump design ensures continuous operation by switching to the other power supply in case of failure.

Stable Flow: The system maintains stable flow even when servers are removed from the cabinet, unaffected by dismantling.

Leak Detection: The system can detect liquid leaks in both the CDU and the cooling module, improving safety.

Customized Production: Tailored recommendations for flow rate, temperature, pipeline design, plate heat exchanger style, etc., are offered to create a customized CDU based on customer needs.

CDU Using: Capable of completing design for Cooling Distribution Units instead of immersion cooling system and has cheaper price.

Key Parameters: Key parameters in plate heat exchanger analysis include chevron angle, corrugation height, corrugation pitch, plate thickness, plate length, plate width, port diameter, port length, channel profile aspect ratio, and surface enlargement factor.

Industrial Applications: Due to their high performance, compactness, and ease of maintenance and cleaning, plate heat exchangers have been widely applied in various industrial, aerospace, and energy production fields.

This summary highlights the key functions and design features of plate heat exchangers in CDUs, emphasizing their importance in thermal management for data centers.