· Product Introduction

The application of plate heat exchangers (PHEs) with non-equal flow channels in the heating, ventilation, and air conditioning (HVAC) industry is primarily reflected in their efficient heat transfer performance and compact design. These heat exchangers use metal plates with different corrugation patterns to form multiple thin rectangular channels for heat exchange between fluids while preventing direct contact between them. PHEs are suitable not only for liquid-liquid and liquid-vapor heat exchange but also for recovering and reusing waste heat in HVAC systems, reducing energy consumption, and improving system efficiency.

In HVAC systems, plate heat exchangers can be used in various applications, such as heat exchangers on the cold and hot source sides of air conditioning systems for heat exchange between chilled water and cooling water; in fresh air treatment to improve the efficiency of heat and moisture exchange; and in heat recovery systems, such as recovering the heat from air conditioning condensate water, as well as in ground source heat pump systems for heat exchange between soil, groundwater, and the air conditioning cold and hot water.

The design principles of plate heat exchangers include meeting process requirements, achieving compactness and miniaturization, selecting plate types with high efficiency and low resistance, considering the convenience of manufacturing, installation, and maintenance, and designing anti-corrosion and anti-scaling measures to extend service life. When selecting a model, it is necessary to consider various thermal and hydraulic parameters such as flow rate, heat exchange area, and medium parameters to ensure that the heat exchanger can meet specific application requirements.

Moreover, the advantages of plate heat exchangers in HVAC systems include high heat transfer coefficients, small size and light weight, ease of disassembly and cleaning, structural strength to withstand high working pressures, high heat transfer efficiency, and low fixed investment. These features make plate heat exchangers an ideal heat exchange equipment in HVAC systems, helping to achieve energy saving and improve the overall performance of the system.

· Model

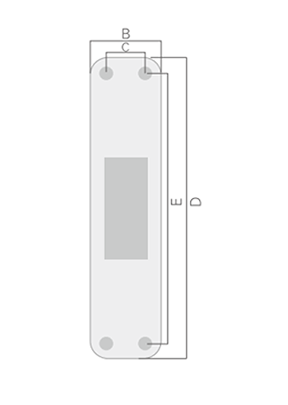

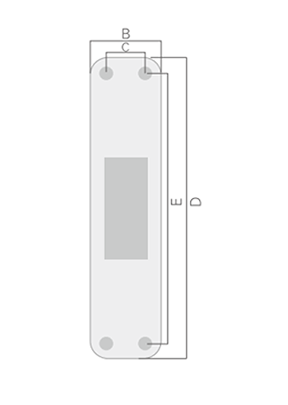

ZL62(F) |

B(mm) 120 | C(mm) 63 | D(mm) 527 | E(mm) 470 | Thickness ( mm ) 10+1.98N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 2.379+0.18N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.