· Product Introduction

Brazed plate heat exchangers (BPHEs) are indeed a highly effective solution for heat transfer applications, offering a range of benefits that can enhance the performance and efficiency of heating and cooling projects. Here's an overview of why BPHEs are such a valuable technology:

Minimal Maintenance: BPHEs are virtually maintenance-free due to the absence of gaskets and the robustness of the brazed construction, which reduces the need for ongoing upkeep.

Reliability: The brazed construction ensures a secure connection between the plates, providing a leak-proof and durable heat exchanger that can operate reliably under various conditions.

High Thermal Efficiency: BPHEs are designed with thin, closely spaced plates that provide a large surface area for heat transfer, which results in high thermal efficiency.

Customization: BPHEs can be customized to meet specific application needs, including different plate materials, corrugation patterns, and flow configurations.

Versatility: They are suitable for a wide range of applications, from HVAC systems to industrial processes, and can handle various types of fluids.

Environmentally Friendly: BPHEs often use less refrigerant due to their high efficiency, which can contribute to a lower environmental impact.

Long Service Life: The robust construction and quality materials used in BPHEs contribute to a long service life, reducing the need for frequent replacements.

Ease of Installation: BPHEs are generally easy to install and integrate into existing or new systems.

Heat Recovery: They are excellent for heat recovery applications, capturing waste heat that would otherwise be lost.

· Model

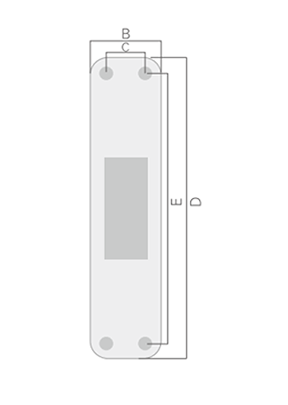

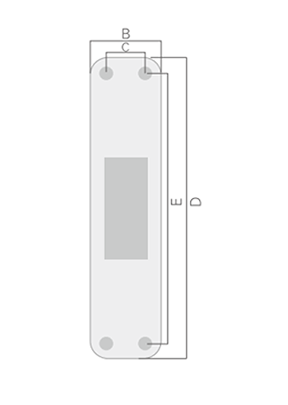

ZL20A |

B(mm) 93 | C(mm) 40 | D(mm) 323 | E(mm) 269 | Thickness ( mm ) 9+1.25N |

Max flowrate ( m3/h ) 8 |

Weight ( Kg ) 1+0.09N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.