Product Introduction

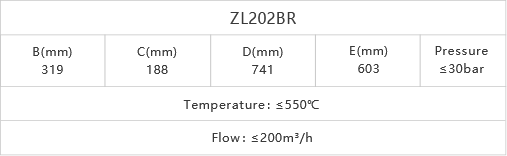

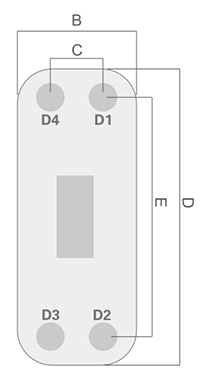

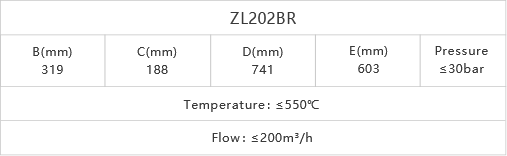

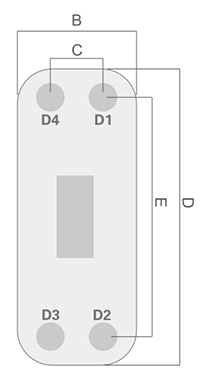

Model

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Characteristics

Fusion-bonded plate heat exchangers represent an advanced technology in heat transfer equipment, providing several key benefits and features that make them suitable for a range of demanding applications. Here are some of the main characteristics of fusion-bonded plate heat exchangers

All Stainless Steel Construction: These heat exchangers are made entirely of stainless steel, which provides superior corrosion resistance and makes them ideal for hygienic applications where contamination from materials like copper or nickel is unacceptable.

Corrosion Resistance: They resist corrosion from aggressive media and process fluids, making them suitable for applications with harsh chemical environments.

Hermetic Seal: The fusion bonding process creates a hermetic seal, ensuring that the fluids being heated or cooled do not mix and that there is no risk of leakage.

Wide Range of Applications: Fusion-bonded plate heat exchangers are used in various applications, including industrial refrigeration, HVAC systems, fuel cell systems, and processes involving high cleanliness demands.

High Mechanical Strength: The bonding process provides a heat exchanger with mechanical strength equivalent to fully welded counterparts, making it reliable under demanding conditions.

Customization: These heat exchangers can be designed with different numbers of plates in single or multi-pass configurations, and various connection interfaces to suit specific application needs.