· Product Introduction

· Model

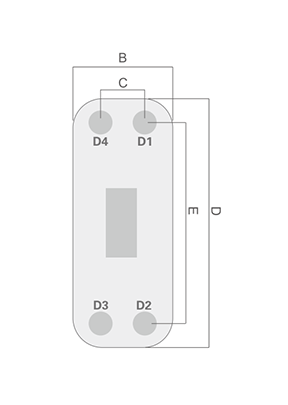

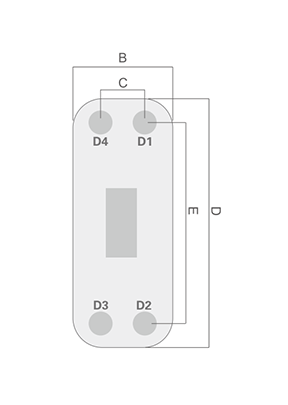

ZL20B |

B(mm) 778 | C(mm) 42 | D(mm) 318 | E(mm) 282 | Thickness ( mm ) 9+2.3N |

Max flowrate ( m3/h ) 8 |

Weight ( Kg ) 1+0.08N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Brazed heat exchangers for condenser applications are recognized for their compact and efficient design. They are engineered to provide high thermal performance within a small footprint, which is ideal for space-constrained installations. The vacuum brazing process used to manufacture these heat exchangers ensures a leak-free and durable construction, suitable for demanding condensing duties.

These heat exchangers typically consist of thin, corrugated stainless steel plates that are brazed together using a material like copper. This process eliminates the need for gaskets and results in a strong, sealed unit capable of withstanding high pressures and temperatures. The absence of gaskets also contributes to lower maintenance requirements, as there are no seals that can wear out or fail over time.

The plate design of brazed heat exchangers promotes turbulent flow, which enhances heat transfer and allows for greater efficiency compared to traditional shell-and-tube heat exchangers. This high efficiency can lead to energy savings and improved performance in systems where the condenser plays a critical role.

Moreover, brazed heat exchangers are customizable to fit specific application needs. They can be tailored in terms of plate patterns, materials, and configurations to optimize performance for the particular condensing conditions required.

For condenser applications, brazed heat exchangers are particularly useful in refrigeration and air conditioning systems, where they help to efficiently condense refrigerant vapor back into liquid, thereby releasing heat to the surrounding environment. Their compact size, high efficiency, and robust construction make them a popular choice for these and other industrial applications where reliable and effective heat rejection is necessary.

Overall, brazed heat exchangers offer a range of benefits for condenser applications, including improved thermal performance, compact design, durability, and low maintenance, making them a preferred choice in many modern heating, ventilation, and air conditioning (HVAC) systems as well as in industrial processes.