Product Introduction

Plate heat exchanger is a high-efficiency heat exchanger equipment composed of multi-layer corrugated heat transfer plates at certain intervals, welded or pressed by rubber gaskets, and is divided into detachable heat exchanger and all-welded heat exchanger according to its processing technology, and semi-welded heat exchanger is a structure between the two, that is, the two fluids are assembled as relatively independent structures; In order to increase the area and rigidity of the heat exchange plate, the heat exchange plate is stamped into various corrugated shapes, and most of them are V-shaped grooves at present, when the fluid forms turbulence in the state of low flow rate, so as to strengthen the effect of heat transfer and prevent the formation of scaling on the plate. The four corner holes on the plate are designed as distribution pipes and discharge headers for fluids, and the two heat exchange mediums flow into their respective flow channels respectively to form a countercurrent through each plate for heat exchange.

Features of gasket plate heat exchanger:

(1) The heat transfer efficiency is greatly improved due to the use of 0.5mm stainless steel sheet.

(2) Small size, which not only saves metal materials, but also reduces the floor space.

(3) Flexible assembly, easy to implement standard work, thus bringing the possibility of further reducing production costs.

(4) It is not easy to scale, easy to clean, and easy to maintain.

(5) Due to the small size and fast response, the operating heat loss is small.

(6) The disadvantage of brazed plate heat exchanger is that the brazing process is demanding and the cost increases.

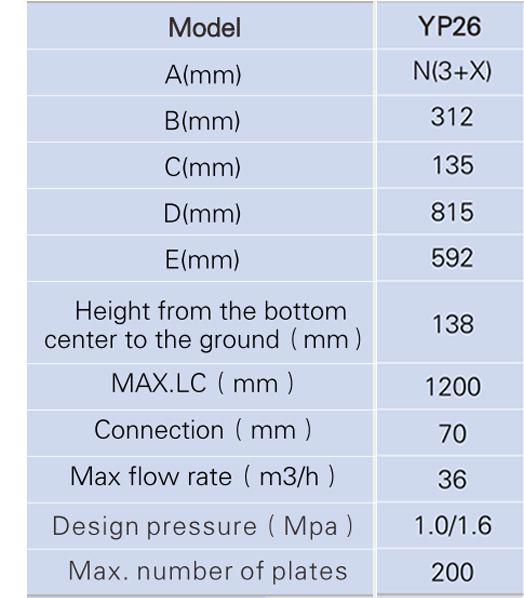

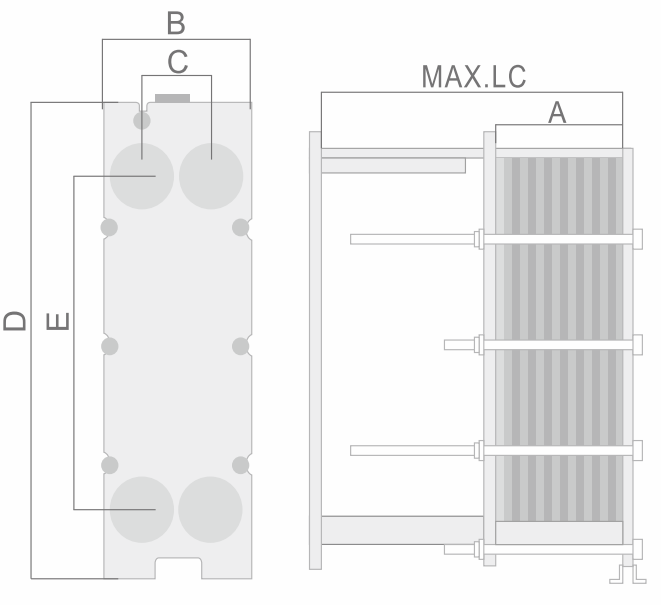

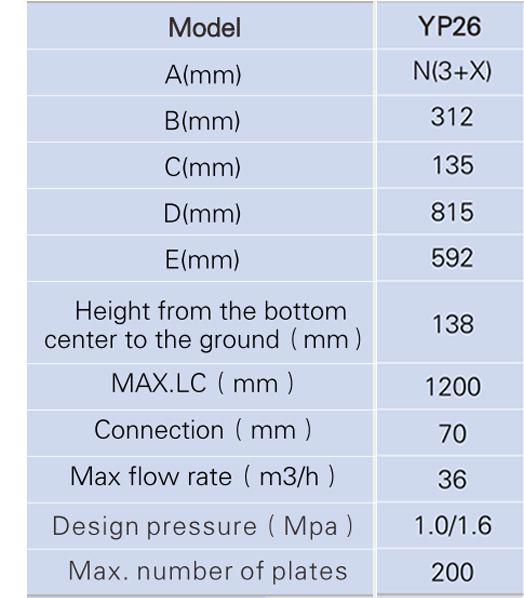

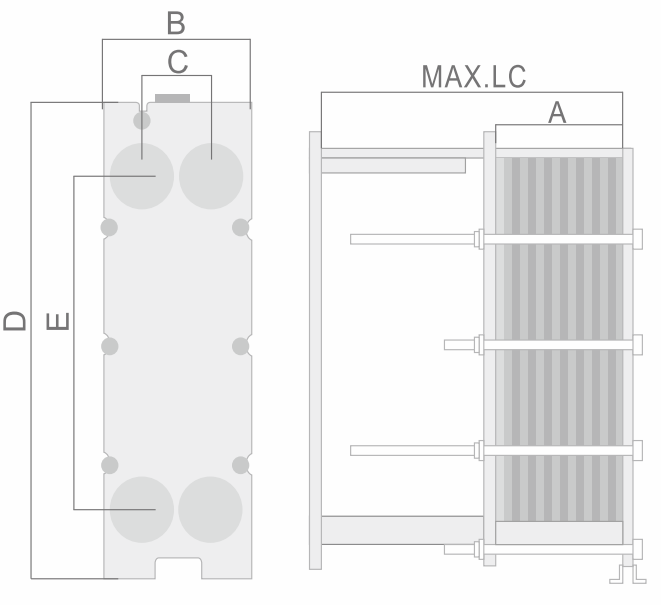

Model

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.