· Product Introduction

· Model

ZL30 |

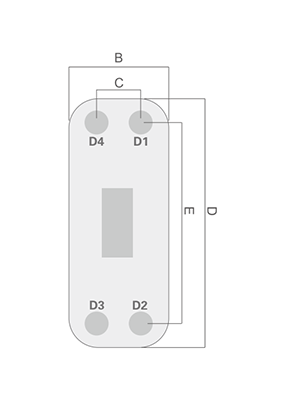

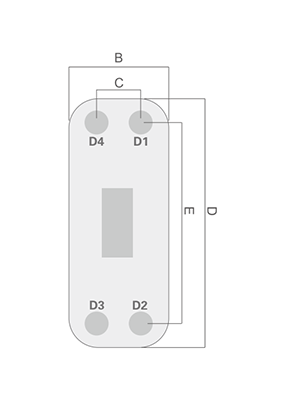

B(mm) 126 | C(mm) 70 | D(mm) 307 | E(mm) 250 | Thickness ( mm ) 10+2.35N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 2.2+0.16N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

ZL30 copper brazed plate heat exchanger is an efficient heat exchanger designed for heat pump system. According to the information provided, the ZL30 heat exchanger has the following characteristics:

Model and design pressure: The ZL30 heat exchanger has different design pressure options, such as 3/4.5MPa.

Size: The size of the heat exchanger can be customized according to needs, with a basic size of 304124(13+2.4n) mm.

Connection material: The connection material of the heat exchanger is AISI316L/304, which is a stainless steel material commonly used in corrosion resistant environments.

Brazing materials: The ZL30 heat exchanger uses copper, nickel or 100% stainless steel as brazing materials, which ensure the stability and durability of the heat exchanger in high pressure and vibration environments.

Weight: The weight of the heat exchanger will vary according to the specific model and size, but a reference value is 2.2+0.16n kg.

Warranty period: ZL30 type heat exchanger usually provides 1 year warranty service.

Application: The ZL30 heat exchanger is suitable for a variety of heat pump systems, including but not limited to domestic and commercial use, providing efficient heat exchange performance.

Technological innovation: Some manufacturers may adopt innovative technologies, such as Micro PlateTM technology, to improve heat transfer efficiency.

Performance: ZL30 heat exchanger because of its efficient heat transfer performance and compact design, can provide better heat energy utilization for the heat pump system, help to improve the overall energy efficiency of the system.

Durability: Due to the use of high-quality materials and brazing process, the ZL30 heat exchanger has good durability and corrosion resistance, suitable for long-term operation in harsh environments.

When selecting ZL30 copper brazed plate heat exchanger, the specific needs of the system should be considered, including the required heat exchange, working pressure, working temperature and installation space. Manufacturers usually provide detailed product specifications and customized services to meet the needs of different customers.