· Product Introduction

· Model

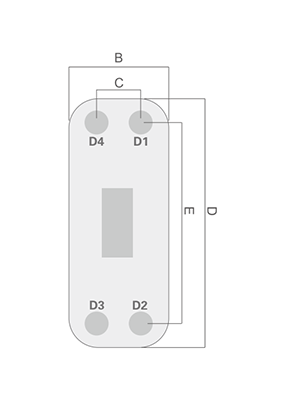

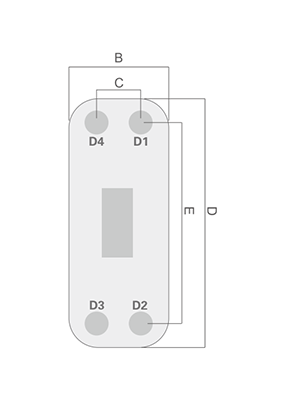

ZL95 |

B(mm) 189 | C(mm) 92 | D(mm) 616 | E(mm) 519 | Thickness ( mm ) 11+2.7N |

Max flowrate ( m3/h ) 42 |

Weight ( Kg ) 7.8+0.44N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Brazed plate heat exchangers (BPHEs) are renowned for their effectiveness in heat transfer applications. Here is a brief overview of how they achieve these benefits:

Unparalleled Performance: BPHEs offer high thermal efficiency due to their compact design and the large surface area for heat exchange provided by the closely spaced plates.

Lowest Lifecycle Cost: While the initial cost of a brazed heat exchanger might be higher than other types, the overall lifecycle cost is typically lower. This is due to their durability, lower energy consumption, and reduced maintenance requirements.

Space Saving: The compact nature of BPHEs allows them to be used in applications where space is limited, making them an ideal choice for installations with space constraints.

Energy Saving: The high efficiency of BPHEs means that less energy is required to transfer heat, leading to significant energy savings and reduced operating costs.

Maintenance Costs: BPHEs are designed to minimize maintenance. The brazed construction is leak-proof and does not require gasket replacement, which can be a significant maintenance task in other types of heat exchangers.

Reliability: The brazed joints provide a secure connection between the plates, ensuring the heat exchanger can operate reliably under a variety of conditions.

Customization: BPHEs can be customized to meet the specific needs of different heating or cooling projects. This includes different plate materials, corrugation patterns, and flow configurations.

Long Service Life: The robust construction and quality materials used in BPHEs contribute to a long service life, reducing the need for frequent replacements.

Environmentally Friendly: BPHEs often use less refrigerant due to their high efficiency, which can contribute to a lower environmental impact.

Versatility: They are suitable for a wide range of applications, from HVAC systems to industrial processes, and can handle various types of fluids.

By leveraging the benefits of brazing technology, your next heating or cooling project can achieve high performance and efficiency, leading to cost savings and a smaller environmental footprint.