· Product Introduction

· Model

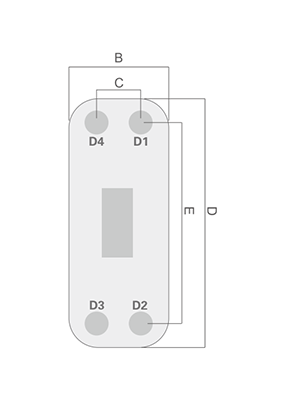

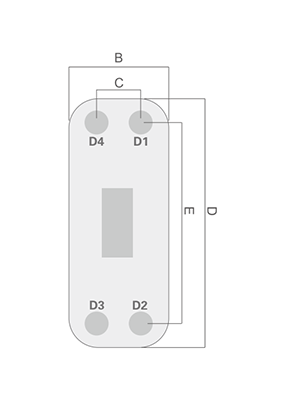

ZL120 |

B(mm) 246 | C(mm) 174 | D(mm) 528 | E(mm) 456 | Thickness ( mm ) 10+2.34N |

Max flowrate ( m3/h ) 42 |

Weight ( Kg ) 7.2+0.52N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Brazed plate heat exchangers (BPHEs) are engineered devices designed for efficient heat transfer between fluids. They are widely used across various industries due to their numerous advantages. Here's an in-depth look at BPHEs:

Construction:

Plates: BPHEs consist of a series of thin, flat plates made from materials such as stainless steel. These plates have a pattern of grooves or corrugations that create the flow channels for the fluids.

Brazing Material: The plates are bonded together using a brazing material, typically copper or a copper alloy, which is heated in a vacuum furnace to join the plates without melting them.

Frame: While the plates are brazed together, a frame is often used to provide structural support for the entire assembly.

Operation:

Fluids enter the heat exchanger through designated ports and flow through the alternating channels created by the corrugated plates.

Heat is transferred between the fluids by conduction through the metal plates, which have a large surface area in contact with the fluids.

The fluids exit through separate ports, having been heated or cooled as required.

Advantages:

Compactness: BPHEs are compact due to the large surface area packed into a small volume, making them ideal for applications where space is at a premium.

Efficiency: The thin plates and close spacing enhance heat transfer efficiency, often outperforming other types of heat exchangers.

Low Maintenance: With no gaskets and a robust brazed construction, BPHEs require minimal maintenance.

Reliability: The brazed joints are secure and do not degrade over time like gaskets can, leading to a reliable and long-lasting heat exchanger.

Customization: BPHEs can be customized with different plate materials, corrugation patterns, and sizes to suit specific applications.

Energy Efficiency: Due to their high thermal efficiency, BPHEs can lead to energy savings.