· Product Introduction

· Model

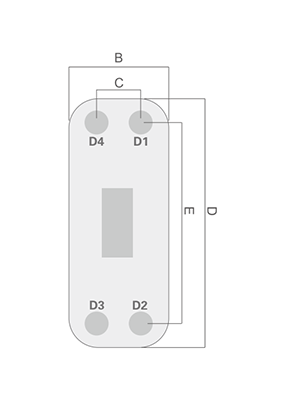

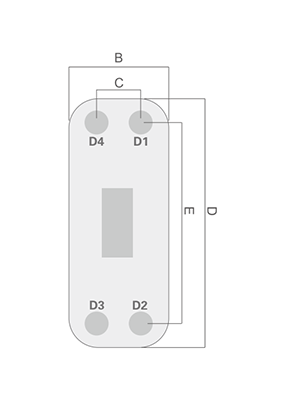

ZL52 |

B(mm) 111 | C(mm) 50 | D(mm) 526 | E(mm) 466 | Thickness ( mm ) 9+2.32N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 2.6+0.21N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

In the refrigeration industry, chillers and heat pumps often rely on brazed plate heat exchangers for their efficient and compact heat transfer capabilities. Here's how they are applied:

Chiller Applications: Brazed plate heat exchangers are used in chillers as evaporators where the refrigerant absorbs heat, leading to cooling. They are also used as condensers to release heat from the refrigerant back into the environment, often with the aid of cooling water or air .

Heat Pump Systems: In heat pump systems, these heat exchangers efficiently transfer heat from a lower temperature source to a higher temperature heat sink, which is essential for space heating and hot water applications .

High-Performance Demands: Danfoss, a leading manufacturer, offers brazed plate heat exchangers with Micro Plate technology that provides up to 10% better heat transfer, crucial for high-performance applications like those found in the refrigeration industry .

Compact Design: The compact nature of brazed plate heat exchangers makes them ideal for applications where space is at a premium, such as in commercial refrigeration or when installing heat pumps in tight spaces .

Efficiency and Longevity: Alfa Laval, another industry expert, emphasizes the greater efficiency and longer lifecycle of their brazed plate heat exchangers, which is beneficial for the continuous operation required in chiller and heat pump systems .

Customization: Companies like Danfoss provide customizable brazed plate heat exchangers, allowing for the tailoring of heat transfer capacity, number of plates, and connection configurations to fit specific refrigeration or heat pump needs .

Reliability: The brazed construction of these heat exchangers ensures a leak-free and reliable operation, which is essential in maintaining the performance and uptime of refrigeration and heat pump systems .

Temperature and Pressure Ratings: With a wide range of temperature and pressure ratings, brazed plate heat exchangers can handle the diverse conditions present in both chiller and heat pump applications .