· Product Introduction

Wall-hung boilers that utilize heat exchangers are commonly found in industrial settings for a variety of applications. Here's how heat exchangers are used in industrial wall-hung boilers:

Space Heating: Industrial spaces often require significant heating due to their size and the need to maintain a comfortable working environment. Wall-hung boilers with heat exchangers efficiently transfer heat to the surrounding air, providing uniform heating .

Process Heating: In some industries, heat is required for processes rather than for comfort. Heat exchangers in wall-hung boilers can be used to provide the necessary thermal energy for industrial processes, such as drying, curing, or chemical reactions .

Hot Water Supply: Industrial facilities may need a constant supply of hot water for various purposes, including cleaning, sanitizing, or for use in manufacturing processes. Heat exchangers in boilers ensure that water is heated to the required temperature .

Energy Efficiency: By using heat exchangers, boilers can achieve higher energy efficiency by capturing and utilizing more of the heat produced during combustion, which is crucial for reducing operating costs in an industrial context .

Modular Design: Wall-hung boilers with heat exchangers often have a modular design, allowing for scalability and flexibility in installations where multiple boilers may be used to meet the heating demands of larger industrial spaces .

Low Maintenance: Industrial boilers with heat exchangers are typically designed for low maintenance, which is an important consideration in industrial applications where downtime can be costly .

Reliability: The use of heat exchangers in wall-hung boilers contributes to the reliability of the heating system, ensuring consistent performance even in demanding industrial environments .

Compliance with Regulations: Industrial boilers must meet strict safety and emissions standards. Heat exchangers help in achieving compliance with these regulations by efficiently transferring heat and reducing the emission of pollutants .

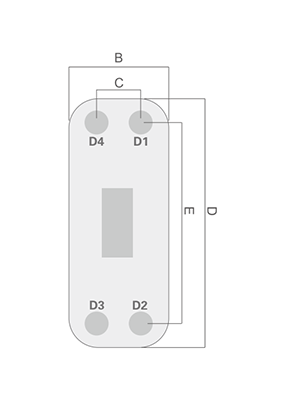

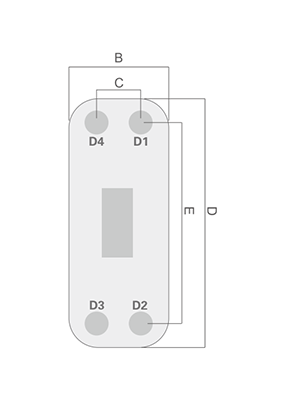

· Model

ZL53 |

B(mm) 106 | C(mm) 50 | D(mm) 522 | E(mm) 466 | Thickness ( mm ) 9+2.1N |

Max flowrate ( m3/h ) 18 |

Weight ( Kg ) 2.6+0.27N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.