Product Introduction

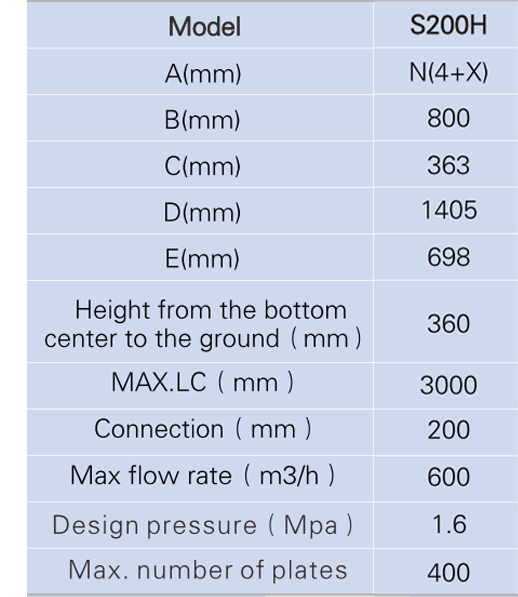

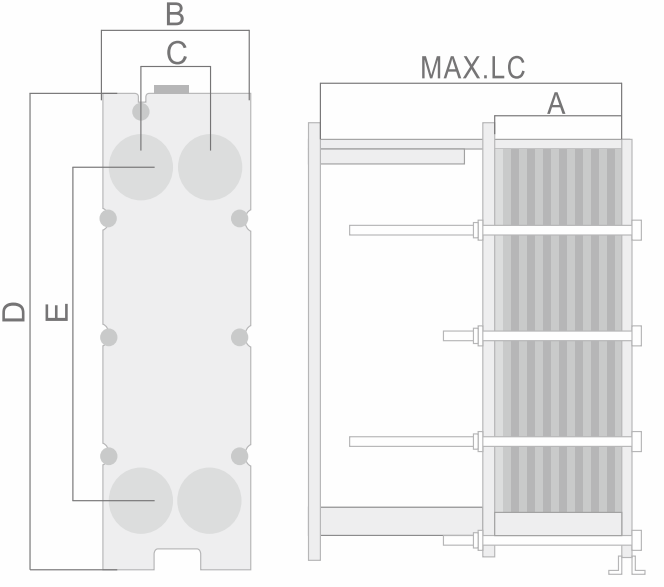

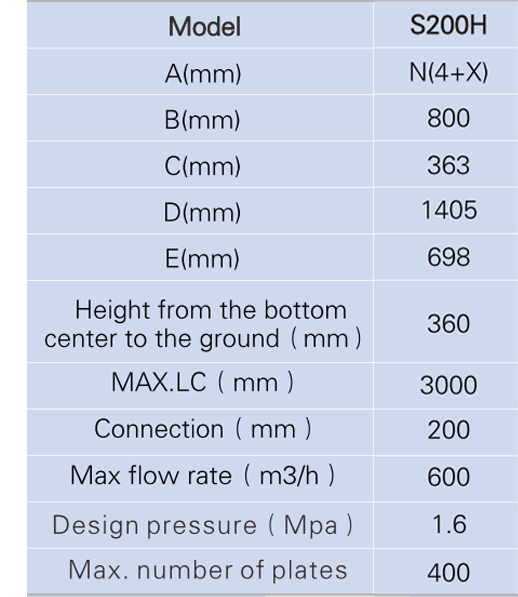

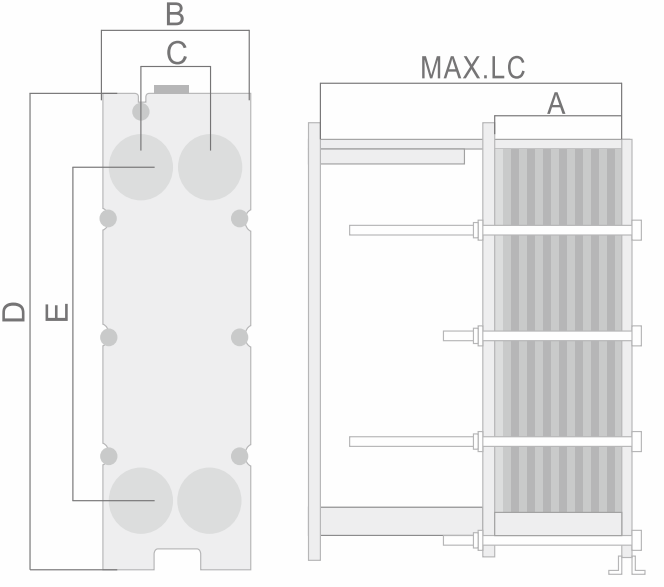

Model

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Characteristics

Gasket heat exchangers, also known as plate-and-frame heat exchangers, have several key characteristics that make them suitable for a variety of applications:

Flexibility and Customization: Gasket heat exchangers can be easily customized by adding or removing plates to meet specific heat transfer requirements. This allows for a tailored solution to fit the needs of different processes.

Ease of Maintenance: The ability to remove and replace gaskets without major disassembly makes maintenance straightforward. This is particularly beneficial for applications where regular cleaning or inspection is required.

Reliability: With proper selection and maintenance of gaskets, gasket heat exchangers can offer reliable and consistent performance over time.

Leakage Prevention: The gaskets provide a seal between the plates, preventing the mixing of different fluids and ensuring that each fluid remains contained within its designated flow path.

Temperature and Pressure Range: Gasket materials can be chosen to withstand a wide range of temperatures and pressures, making these heat exchangers suitable for various industrial applications.

Compact Design: Plate heat exchangers generally have a smaller footprint compared to shell-and-tube heat exchangers, which is advantageous in space-constrained environments.

Energy Efficiency: The thin and closely spaced plates provide a large surface area for heat transfer, which can lead to high thermal efficiency and energy savings.

Low Fluid Residence Time: The short flow paths in plate heat exchangers can reduce the residence time of fluids, which is beneficial for heat-sensitive applications.

Material Compatibility: Plates can be made from a variety of materials, including stainless steel, titanium, and other alloys, to suit the chemical properties of the fluids being processed.

Hygiene: The design allows for complete drainage and can be easily cleaned, making gasket heat exchangers suitable for applications in the food, dairy, and pharmaceutical industries where hygiene is critical.

Scalability: The modular nature of plate-and-frame heat exchangers allows for easy scaling up or down of the heat transfer capacity by adding or removing plates.

Heat Transfer Rate: The corrugated plates enhance the turbulence of the fluid flow, which can increase the heat transfer rate and reduce the overall size of the unit.

These characteristics make gasket heat exchangers a popular choice in many industries, offering a balance of performance, flexibility, and ease of use.