· Product Introduction

"Smoke Type Brazed Heat Exchanger for Heat Recovery" refers to a brazed plate heat exchanger designed for recovering heat from flue gases or similar high-temperature gas streams. Such heat exchangers are widely utilized in industrial processes to recuperate thermal energy from flue gases, which enhances overall energy efficiency and reduces operational expenses. These brazed plate heat exchangers are favored for their compact construction, superior heat transfer capabilities, and ease of maintenance.

The provided search results highlight various aspects of brazed plate heat exchangers, including their design, applications, performance enhancement techniques, and detailed experimental studies. For example, there are studies discussing the flow boiling and pressure drop characteristics of brazed plate heat exchangers within the context of power systems that utilize the organic Rankine cycle. Other research explores the overall performance of a prototype brazed plate heat exchanger across different Reynolds number ranges. Additionally, there is research examining the application of nanofluids in plate heat exchangers to improve heat transfer efficiency.

Innovative technologies that enhance the performance and reliability of brazed plate heat exchangers are also highlighted in the literature. These include systems that ensure high heat transfer performance and dual-circuit designs that provide uniform cooling and maximize performance even at partial loads.

The information indicates that brazed plate heat exchangers are a significant asset in heat recovery applications. With ongoing technological advancements, these heat exchangers are instrumental in the pursuit of greater energy utilization efficiency.

· Model

Smoke type brazed plate heat exchanger |

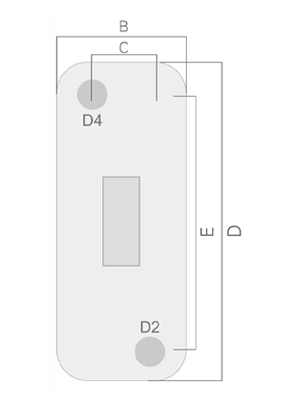

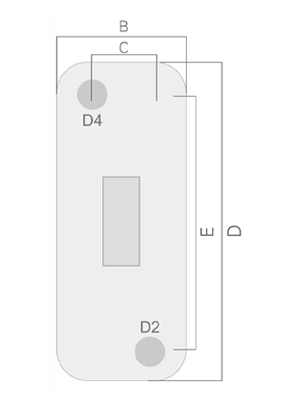

| Model | B(mm) | C(mm) | D(mm) | E(mm) | Thickness(mm) | Weight( Kg ) | Design pressure(Mpa) |

| ZY35 | 124 | 52 | 286 | 227 | 6+3.23N | 1.64+0.124N | 3

|

| ZY36 | 124 | 52 | 286 | 227 | 6+3.23N | 1.64+0.124N | 3 |

| ZY116 | 213 |

| 621 | 476 | 12+2.26N | 12+0.44N | 1.5 |

| ZY150 | 202 |

| 771 | 610 | 12+2.26N | 15+0.5N | 1.5 |

| ZY340 | 490 | 328

| 780 | 578 | 12+2.08N | 36+1.17N | 1.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.