· Product Introduction

· Model

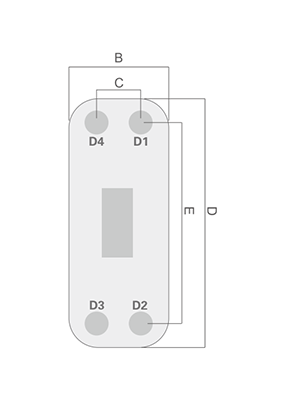

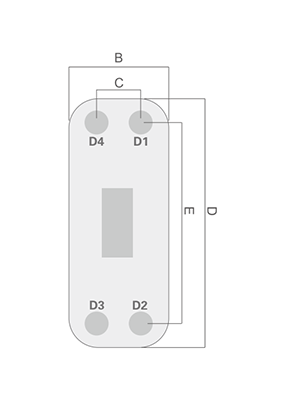

ZL95F |

B(mm) 182 | C(mm) 92 | D(mm) 609 | E(mm) 519 | Thickness ( mm ) 12+2.05N |

Max flowrate ( m3/h ) 42 |

Weight ( Kg ) 15+0.36N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Unilateral Brazed Heat Exchanger for an oil cooler is a specialized type of heat exchanger designed to efficiently cool oil used in various industrial applications. The term "unilateral" typically refers to a design where the heat exchanger is brazed on one side, creating a compact and efficient heat transfer surface. Here are some key aspects of a Unilateral Brazed Heat Exchanger used specifically for oil cooling:

Brazed Construction: The heat exchanger plates are brazed together, which provides a strong, leak-proof seal that can withstand high pressures and temperatures.

Compact Design: Brazed heat exchangers are known for their compact size, which is achieved through the close spacing of the plates. This makes them ideal for applications where space is limited.

High Thermal Efficiency: The close proximity of the plates allows for efficient heat transfer, making it effective for cooling hot oil.

Customizable: The brazed heat exchangers can be customized to meet specific cooling requirements, including the choice of plate material, plate thickness, and the overall size of the heat exchanger.

Low Maintenance: The brazed construction requires less maintenance compared to other types of heat exchangers that use gaskets or seals.

Reliability: Brazed heat exchangers are known for their reliability and long service life, provided they are operated within their design parameters.

Application Specific: The unilateral brazed heat exchanger for an oil cooler is particularly useful in applications such as hydraulic systems, gearboxes, and engines where oil cooling is necessary to maintain optimal operating temperatures.

Energy Efficiency: By effectively cooling the oil, these heat exchangers can contribute to the overall energy efficiency of a system by reducing the load on other cooling systems.

Safety: They are designed to operate safely with flammable or high-temperature oils, ensuring that the cooling process does not pose a risk of fire or other hazards.