· Product Introduction

· Model

JY01 |

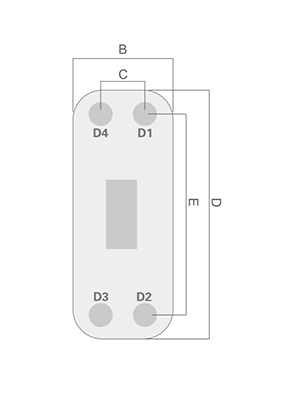

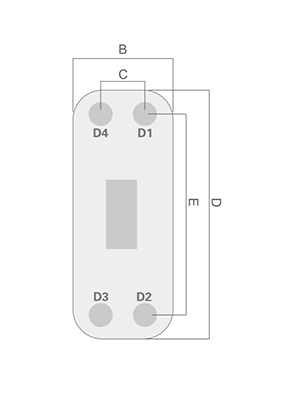

B(mm) 390 | C(mm) 204 | D(mm) 1320 | E(mm) 1132 | Thickness ( mm ) 22+2.75N |

Max flowrate ( m3/h ) 300 |

Weight ( Kg ) 30+1.8N Design pressure ( Mpa) 3/4.5 |

We may modify and upgrade the parameters listed in the drawings and parameter tables without prior notice. The performance parameters and dimensional drawings are subject to order confirmation.

Copper plate heat exchangers are highly valued for their thermal conductivity and resistance to corrosion, making them suitable for a variety of applications, especially in the chemical industry where they can handle different chemicals and conditions. Here are some key points about copper plate heat exchangers:

High Thermal Efficiency: Copper's high thermal conductivity makes it an excellent material for heat transfer applications, allowing for efficient energy use.

Corrosion Resistance: Copper and its alloys have good resistance to corrosion, which is beneficial for handling aggressive chemicals commonly found in the chemical industry.

Compact Design: Copper plate heat exchangers can be designed to be compact, saving space in industrial settings where footprint can be a critical factor.

Easy Maintenance: The design of plate heat exchangers allows for ease of maintenance and cleaning, which is important in industries where hygiene and cleanliness are crucial.

Customization: Copper plate heat exchangers can be customized to meet specific process requirements, including the ability to handle different flow rates and temperatures.

Brazed Construction: Often, copper plate heat exchangers are brazed, which provides a strong, leak-free joint. This construction method is particularly useful for creating hermetic seals that can withstand high pressures.

Versatility: They are used in various applications such as heating, cooling, evaporation, and condensing due to their ability to efficiently manage a range of thermal processes.

Sustainability: Copper's recyclability contributes to the sustainability of these heat exchangers, as they can be easily recycled at the end of their service life.

Enhanced Performance: Research has focused on improving the performance of plate heat exchangers through various methods, such as the use of copper foam to enhance heat transfer coefficients and reduce pressure drop.

Micro-channel Technology: Copper's malleability allows for the creation of micro-channels in plate heat exchangers, which can improve heat transfer efficiency in compact spaces.

Long Service Life: Due to copper's inherent properties, heat exchangers made from this material tend to have a long service life, particularly when properly maintained.

Suitability for High-Performance Applications: Copper plate heat exchangers are suitable for applications that require high heat transfer rates and where the operating conditions are challenging.